I experimented with making the plunger to shoot the ball at the beginning. This was done by threading a steel and attaching a comfortable rubber stopper.

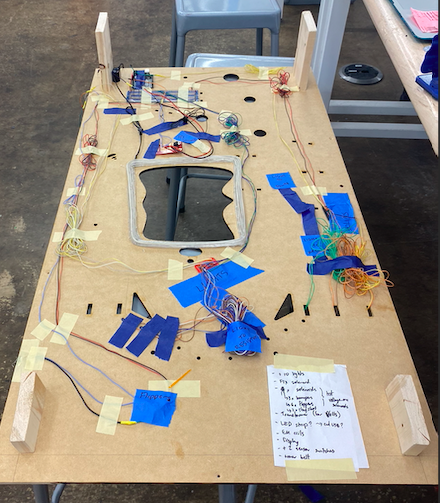

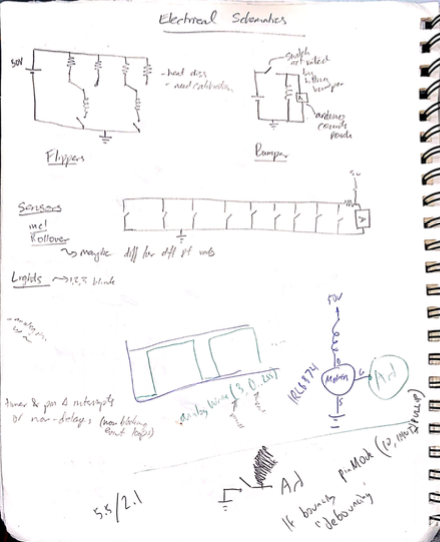

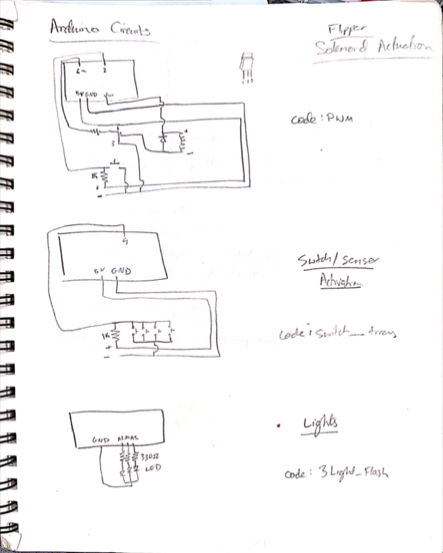

I also worked on integrating the solenoids into my bumpers, slingshots and flipper. I experimented with various solenoids and even made a higher fidelity version with copper wire.

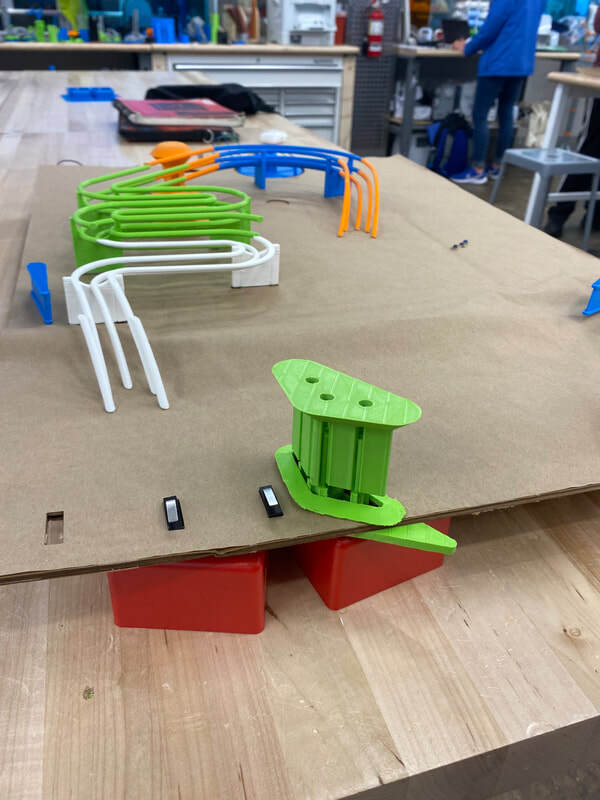

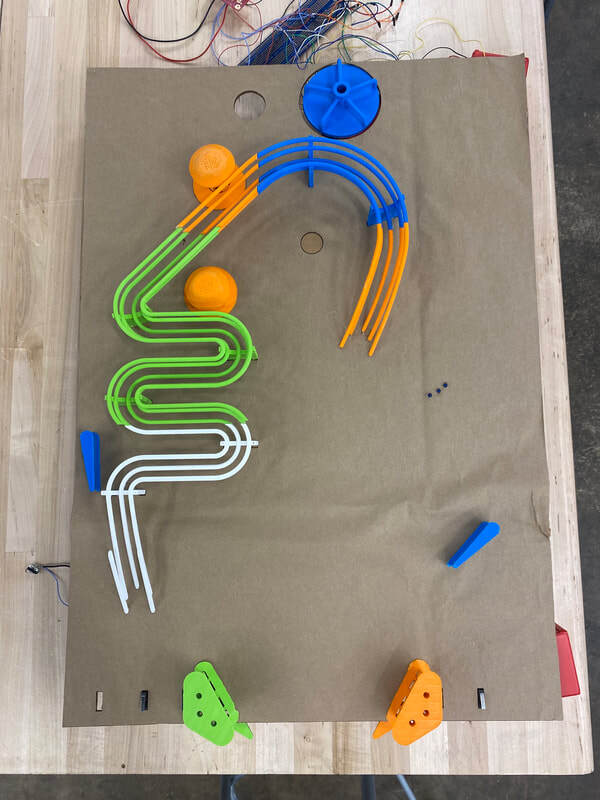

To activate the bumper the arduino must detect contact between the ball and the bumper. To do this I created an open circuit with an exposed side on the ramp of the bumper and one on the face of the pinball machine. This means when the ball rolls over the ramp it will complete the circuit, activate the bumper and get shot away. I experimented with thin copper sheets, copper tape and AlFoil. AlFoil was the best because it was easily moldable, cheap and did not short circuit with itself like the copper tape did.

The various progressions of my design of solenoids and solenoid activated components is at this link.

I also worked on integrating the solenoids into my bumpers, slingshots and flipper. I experimented with various solenoids and even made a higher fidelity version with copper wire.

To activate the bumper the arduino must detect contact between the ball and the bumper. To do this I created an open circuit with an exposed side on the ramp of the bumper and one on the face of the pinball machine. This means when the ball rolls over the ramp it will complete the circuit, activate the bumper and get shot away. I experimented with thin copper sheets, copper tape and AlFoil. AlFoil was the best because it was easily moldable, cheap and did not short circuit with itself like the copper tape did.

The various progressions of my design of solenoids and solenoid activated components is at this link.