- Published on

End of Semester Summary

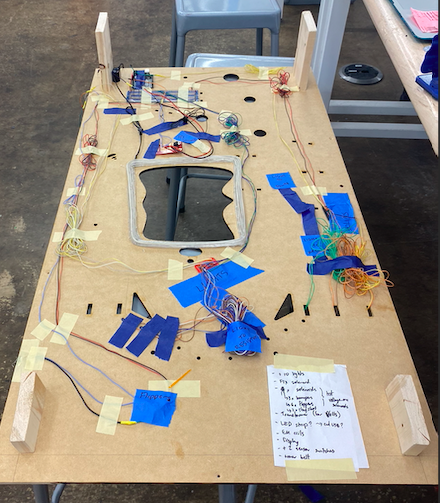

Throughout the semester I spent time taking the code I had previously created and forming an electrical harness for easy debugging on the back. A big problem that occurred was my joints breaking at the protoboard connection. To compensate I added stress relief to the joints.

Additionally, I spent time manufacturing the machine into a higher fidelity prototype. This involved lasercutting the base (mdf with an acrylic cover), adding legs and creating components which effectively fit in the holes.

The component designs were increased to have more high fidelity models which also accounted for the connections each component would need to have to the board.

Additionally, I spent time manufacturing the machine into a higher fidelity prototype. This involved lasercutting the base (mdf with an acrylic cover), adding legs and creating components which effectively fit in the holes.

The component designs were increased to have more high fidelity models which also accounted for the connections each component would need to have to the board.